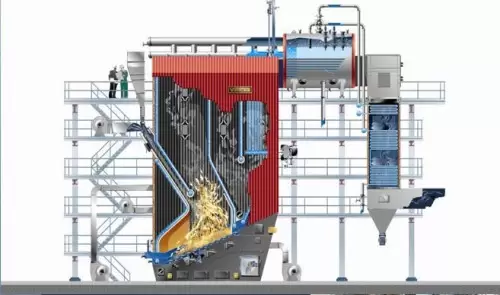

The operation of a boiler system is extremely complex, requiring high principles and skills. This article will help businesses understand the basic steps of fluidized bed boiler operation.

Overview of fluidized bed boiler operation

Normally, to ensure the safe and efficient operation of the fluidized bed boiler, the preparation must be done smoothly and thoroughly.

That is because the components of a fluidized bed boiler will have a complex operating principle and require different operations. Therefore, in order to operate the fluidized bed boiler effectively, the operator has to go through certain difficulties.

For example, the preparation of input fuel to operate a wood-burning boiler is extremely difficult, not to mention that if the boiler is larger, the amount of fuel needed is very large, so it is even more difficult.

And operating a coal-fired boiler is equally complicated. Coal is a fuel that heats up extremely quickly, so equipment needs to be mechanized and automated to ensure safety. Moreover, the recovery of ash and slag when burning coal is also relatively difficult.

That is some overview points about fluidized bed boiler operation. So how will the operation take place?

Operation process of a fluidized bed boiler

Check before going into operation

Before priming the kiln, make sure that the data on the sand layer height, the distance from the nozzle to the bricks have been carefully measured.

Mark the sand layer and then put the sand into the combustion chamber: Normally, the sand layer is about 200mm or more high (calculated from the nozzle). Then dry the sand and bring it to a boil, record the following parameters:

- What is the minimum fan frequency for the sand to boil?

- How much sand does it take to get 200mm tall?

- How far from the nozzle does the sand begin to boil evenly?

- What is the level 1 wind pressure?

After checking, fire!

Fire priming, calibration and operation of coal-fired fluidized bed boiler

Preparation

First, it is necessary to prepare fuel including indo coal with the size of each grain from 1 to 10mm, charcoal weighing about 200kg. Next, arrange from 2 to 3 workers to operate the fluidized bed boiler. Besides, some other necessary items such as 20 – 40 liters of kerosene, 5 to 10 kg rags and 2 coal rakes.

Fire Priming

After you have prepared the necessary materials, you can start priming.

- Put sand into the combustion chamber so that it is 200mm or more high.

- Turn on the fan level 1 at 50Hz to boil the sand layer. After 60 minutes, the sand layer boils evenly, then proceed to dry the sand.

- Turn off the fan and check the combustion chamber. If the sand layer has boiled evenly and reaches a height of 200mm or more, then proceed to the next step.

- Supply coal to the combustion chamber with a height of 30mm or more and ensure that the coal is spread evenly on the sand layer.

- Add the charcoal, rake until even with a fine layer of charcoal.

- Pour kerosene and charcoal layer, soak a rag in oil and put it in the combustion chamber.

- Check the combustion chamber, make sure the charcoal is burning

- Turn on the fan at 3Hz to draw hot air. Continue to watch the fire burn.

- Use a rake to evenly distribute the charcoal, making sure the charcoal burns evenly.

- Turn on the level 1 fan at 15Hz to supply air for the combustion process. Next, turn on the exhaust fan at 7Hz.

- Observe the burning coal layer inside the furnace chamber, gradually raise the sand temperature to 300 degrees Celsius to ensure that the fine coal layer burns evenly.

- When both the charcoal and the fine coals are burning, continue to feed the coals into the furnace to keep the fire burning.

- Turn the level 1 fan up to 25Hz so the sand and coals squirm and start moving. Use a rake to spread the fire evenly.

- Continuously observe the sand temperature, make sure the sand rises to 500 degrees Celsius.

- When that temperature is reached, increase the level 1 fan to 30Hz, the exhaust fan to 12Hz so that the sand boils evenly.

- Continuously feed combustion fuel to gradually raise the temperature of the sand layer. During priming the furnace should open the air release valve.

Stop the boiler

Please contact the factory so that the boiler can be stopped. When stopping the boiler, make sure that the fuel supply system is turned off and that the fuel in the combustion chamber has been burned out. Note that only when the temperature of the sand layer drops below 850 degrees Celsius, the boiler will be stopped.

In addition, turn off the level 1 fan systems, when the level 1 fan stops completely, turn off the exhaust fan system.

Conclusion

Above is the basic procedure for operating a fluidized bed boiler system, direct implementation will have some differences. Therefore, to be able to master how to operate a fluidized bed boiler, please feel free to contact us via:

- Sale Department: +84 975 337 933 (Mr. Khang)

- Technical department: +84 947899363 (Mr. Son)