ENERGY SOLUTION

PROVIDER

10+ years of experience

Reputable partners

comprehensive Ecosystem

Professional personnel

Saturated steam

Providing solutions to optimize energy costs in customers’ production line while meeting environmental regulations

Saturated steam

Invest in a multi-fuel circulating fluidized bed boiler (Biomass/RDF) to provide heat/steam, replacing fossil fuels (oil, gas, coal, etc.)

Centralized steam supply

Building a centralize boiler system and connecting steam pipelines to each customer in the Industrial Park/Cluster, enhancing efficiency and energy stability in production

cogeneration

Provide steam – heat – electricity cogeneration solutions to optimize energy sources and significantly reduce the costs for customers

Operation & Maintenance

Provide professional, efficient boiler operation and maintenance services with quick responses to customers’ needs.

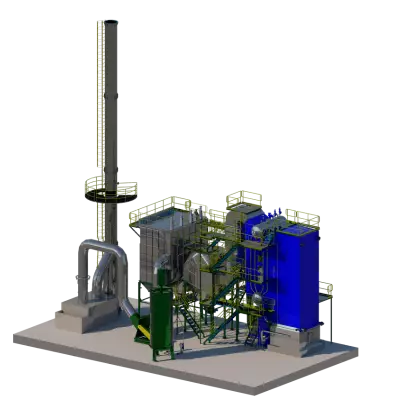

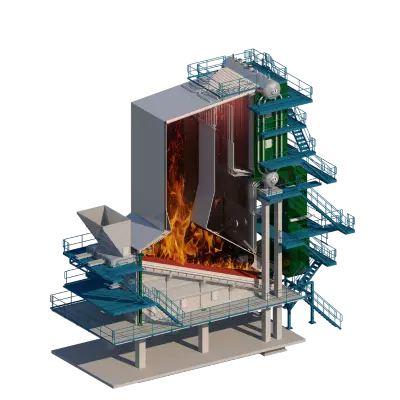

FLUIDIZED BED BOILER

is an advanced combustion system designed for high-efficiency steam generation using biomass

Key Benefits:

- Fuel Flexibility: Burns a variety of fuels, including biomass, industrial waste, and low-grade coal.

- High Efficiency: Enhances combustion with fluidized bed technology, ensuring optimal heat transfer and low emissions.

- Eco-Friendly: Meets Vietnamese emission standards (TCVN-QCVN) with reduced NOx and SOx levels.

- Cost-Effective: Improves fuel utilization, reducing operational costs.

- Stable & Safe Operation: Automated controls ensure steady combustion and long equipment lifespan.

This efficient and sustainable boiler solution supports industries seeking clean energy alternatives while minimizing environmental impact

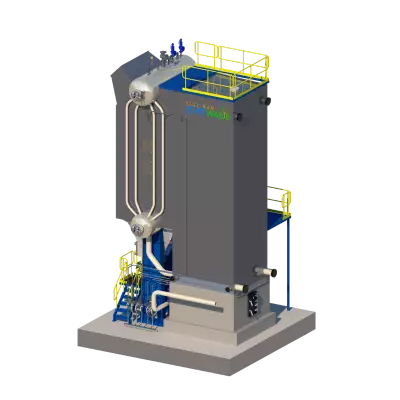

Biomass boiler

is an eco-friendly solution using biomass fuel to generate saturated steam for industrial production.

Key Benefits:

- Sustainable: Uses agricultural and forestry residues, reducing fossil fuel dependence.

- Cost-Efficient: Optimized fuel blending minimizes production costs.

- Eco-Friendly: Meets Vietnamese emission standards (TCVN-QCVN).

- Efficient & Safe: Automated monitoring ensures stable and reliable operation.

- Industry-Ready: Integrated directly into manufacturing processes with on-site supervision.

This system supports sustainable energy use, enhancing efficiency and environmental responsibility

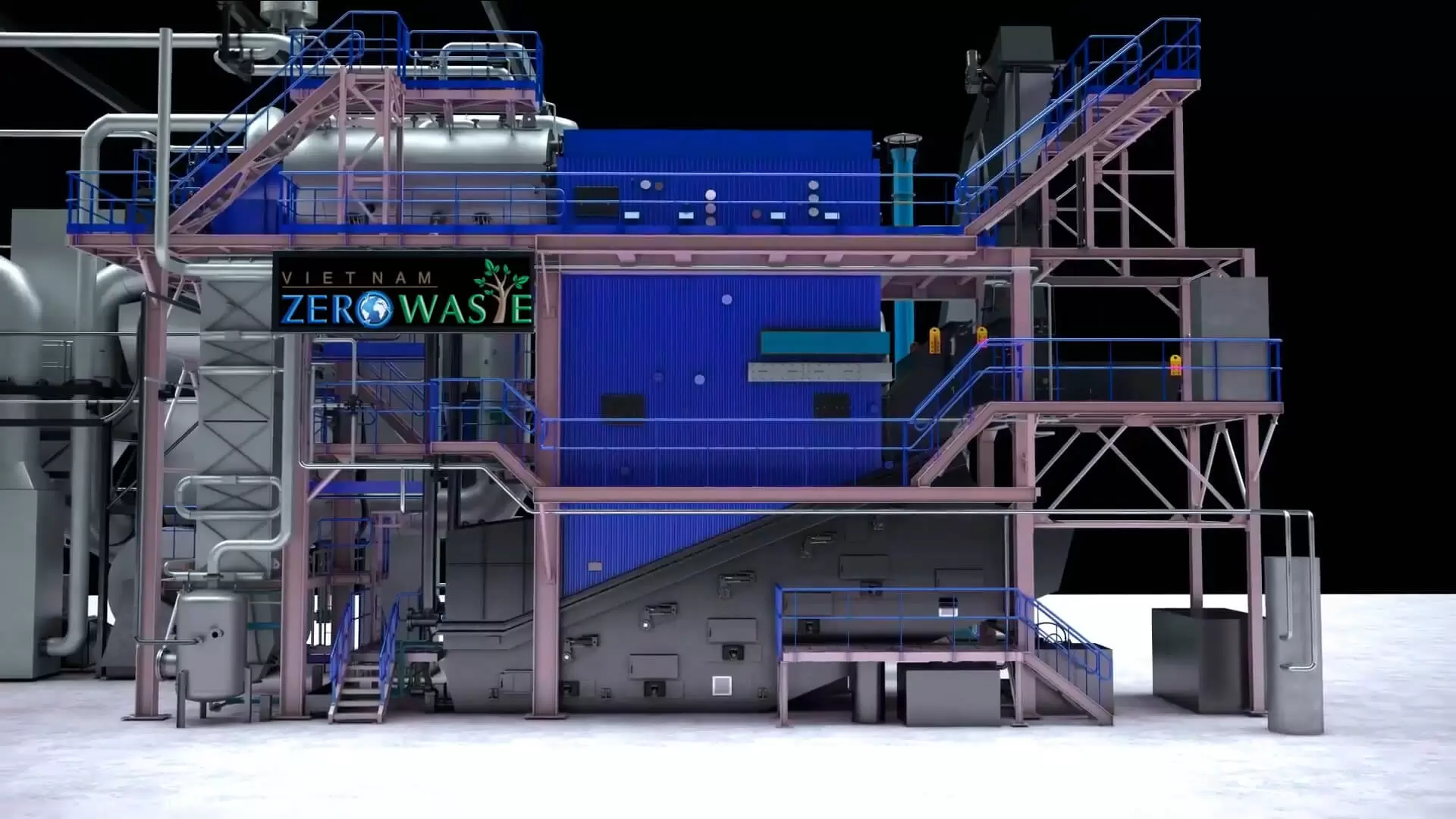

biowaste boiler

is an advanced solution that converts waste into energy, reducing environmental impact while supplying saturated steam for industrial use.

Key Benefits:

- Waste-to-Energy: Burns industrial and organic waste, minimizing landfill disposal.

- Cost-Effective: Reduces fuel expenses by utilizing waste materials.

- Eco-Friendly: Designed to comply with Vietnamese emission standards (TCVN-QCVN).

- Efficient & Safe: Optimized combustion for stable and clean energy generation.

- Industrial Integration: Supports manufacturing operations with on-site waste management.

This boiler promotes sustainability, cost savings, and energy efficiency, aligning with Zero Waste’s commitment to green industrial solutions

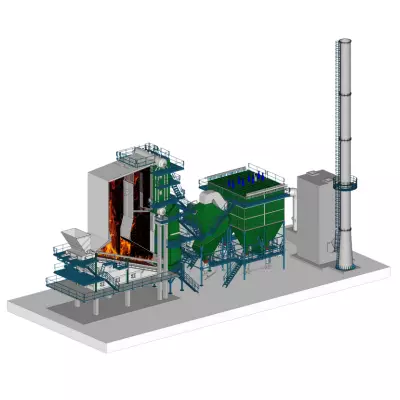

STEP GRATE BOILER

is a high-efficiency biomass and waste combustion system, designed for industrial steam generation with enhanced fuel utilization.

Key Benefits:

- Fuel Versatility: Burns biomass, wood chips, waste, and other solid fuels efficiently.

- Optimized Combustion: Step grate design ensures even fuel burning, reducing unburned residues.

- Eco-Friendly: Complies with Vietnamese emission standards (TCVN-QCVN), minimizing pollutants.

- Energy Efficient: Maximizes heat transfer, lowering fuel consumption and operating costs.

- Durable & Reliable: Designed for stable long-term operation with automated monitoring.

This cost-effective and sustainable boiler supports industries aiming for energy efficiency and environmental responsibility

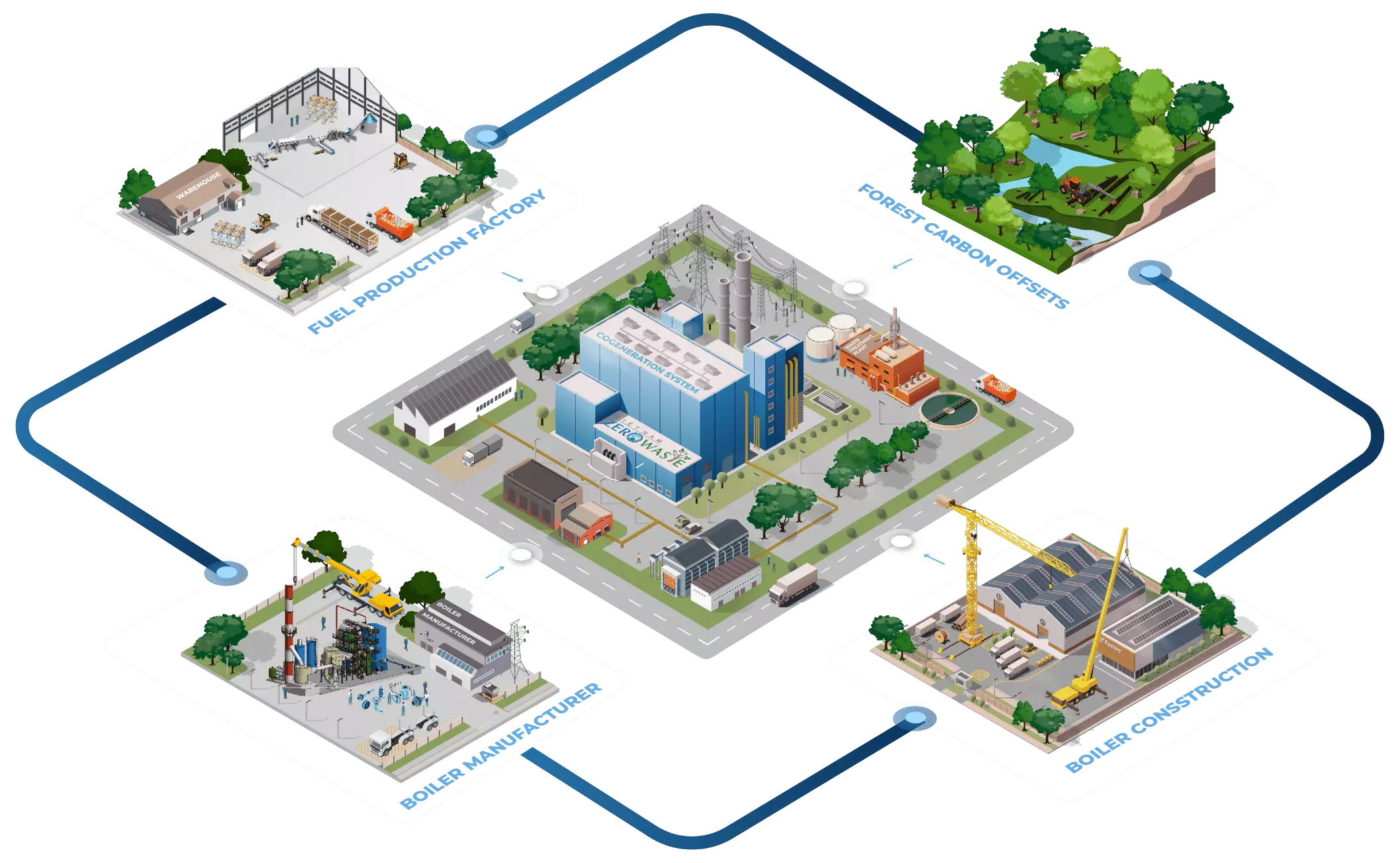

With a professional working model

We are committed to provide the fastest and most effective solution for our customers

1. research & study customer needs

Communicate directly to capture customer needs

2. Evaluate & propose solutions

Actual evaluate, feasibility assessment & detailed design of the project

3. Unification negotiations

Negotiate and agree with customers on technical and financial options

4. Project planning

Agree on the progress of the project implementation

5. fabrication and installation

Procurement of materials, design, manufacture & transport and installation according to committed schedule.

6. acceptance & commissioning

Complete installation - Test run - Official commissioning

Vietnam Zerowaste always is <br>the first choice of customers

our latest news

We are always up to date with the latest news and constantly updated information