The circulating fluidized bed boiler is an effective energy solution in green transformation, helping businesses to move towards a circular economy and sustainable development. How is the boiler system installed by Vietnam Zero Waste and how does it operate?

This article will provide you with detailed information about the installation process of Vietnam Zero Waste circulating fluidized bed boiler system.

Vietnamese enterprises aim to effectively use energy sources and limit negative impacts on the environment. In which, the circular economy model is the solution, an indispensable requirement of sustainable development. So what is the circular economy?

The concept of a circular economy is formed from a basic principle that ‘everything is an input to something else’ (according to the ICED Research Institute for Circular Economy). Simply put, a circular economy is the process of turning the waste output of one industry into an input resource for another.

By using renewable energy, eliminating the use of harmful chemicals and waste through the superior design of materials and products, businesses can add value, reduce resource extraction, reduce waste treatment costs and reduce environmental pollution. Moreover, this is considered an inevitable trend today, when any business that wants to develop sustainably and long-term cannot be ignored.

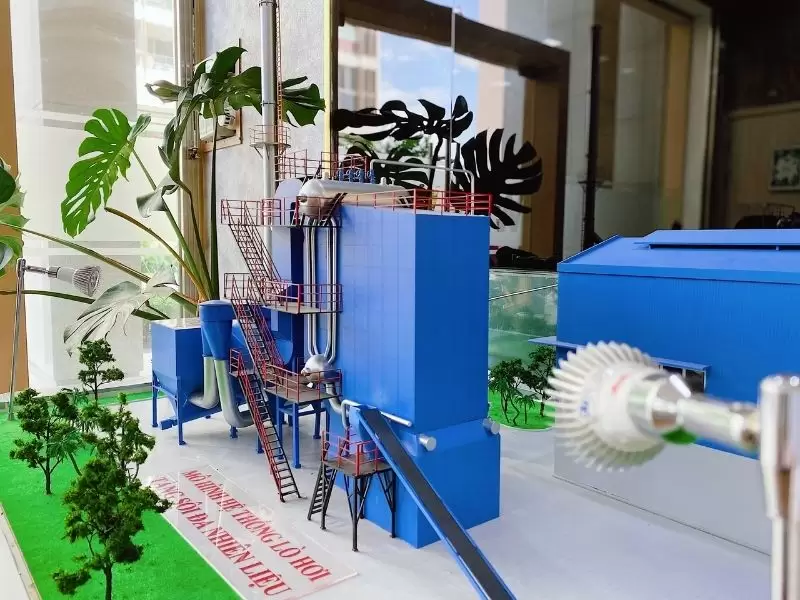

Based on a completely new concept of circular economy, as an energy solution provider, Vietnam Zero Waste has been investing in building and developing a circulating fluidized bed boiler system, with the main function is to convert waste into a useful energy source for customers.

Zero Waste installing circulating fluidized bed boiler technology

Fluidized bed boiler system multi-fuel with outstanding advantages. Typically, it can burn a variety of fuels, which can contribute to reducing a large amount of waste from agro-forestry by-products.

In addition, based on the specific characteristics of each industry and the individual needs of each customer, Zero Waste’s boiler system will be designed – manufactured – operated to suit the energy needs of the company.

The process of implementing a boiler system installation project at Zero Waste includes 6 steps:

- Step 1: Survey and find out the demand for energy by going directly to the customer’s factory or factory.

- Step 2: Evaluate the feasibility, propose the plan from the actual survey step, and provide the detailed design of the option to install the boiler system.

- Step 3: Negotiate and agree with the customer on the technical and financial plan.

- Step 4: Conduct project planning based on the agreement with the customer.

- Step 5: Construction – fabrication and installation according to the schedule commitment.

- Step 6: Complete the installation process, test run and officially operate.

Zero Waste's experienced staff

To get the finished product of the boiler system of high quality and bring efficiency to the business, it is necessary to have the contribution from the experienced staff of Zero Waste. With a team of workers – employees full of energy and high sense of responsibility, Zero Waste is always available to solve the problems that customers encounter during the project implementation period.

Zero Waste with the mission of converting waste into useful clean energy, constantly improving equipment, boiler technology is more and more modern, suitable for your business to achieve the goal of a circular economy and sustainable development.

If you are also aiming for a circular economy or need advice on Zero Waste boiler technology solutions, we are always ready to serve you.

Contact Zero Waste:

- Sales Department: +84 975 337 933 (Mr. Khang)

- Technical Department: +84 947 899 363 (Mr. Son)