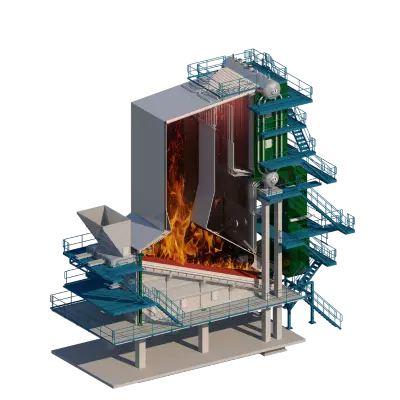

Specification

– Boiler efficiency: 85%

– Capacity: 40MW

– Steam output: 120 tons/h

– Pressure gauge: 10-150 bar

PRICIPLE OF OPERATION

– After the fuel is burned, it is dried and burned to form ash and slag.

– The process of burning this fuel causes water in the tubes to generate steam and put it on the steam drum to separate the mixture of steam and water.

– The final vapor product is saturated steam.

– Exhaust smoke is treated by the feed water heater and the feed air dryer.

– Dust treatment with a dust filter system, ensuring safety and avoiding environmental pollution.

efficiency and application

– Various fuels

– Simple, easy to operate, adjustable

– Automatic operation system, saving labor costs

– Can be applied to industries such as textile dyeing, paper, animal feed, …